Description

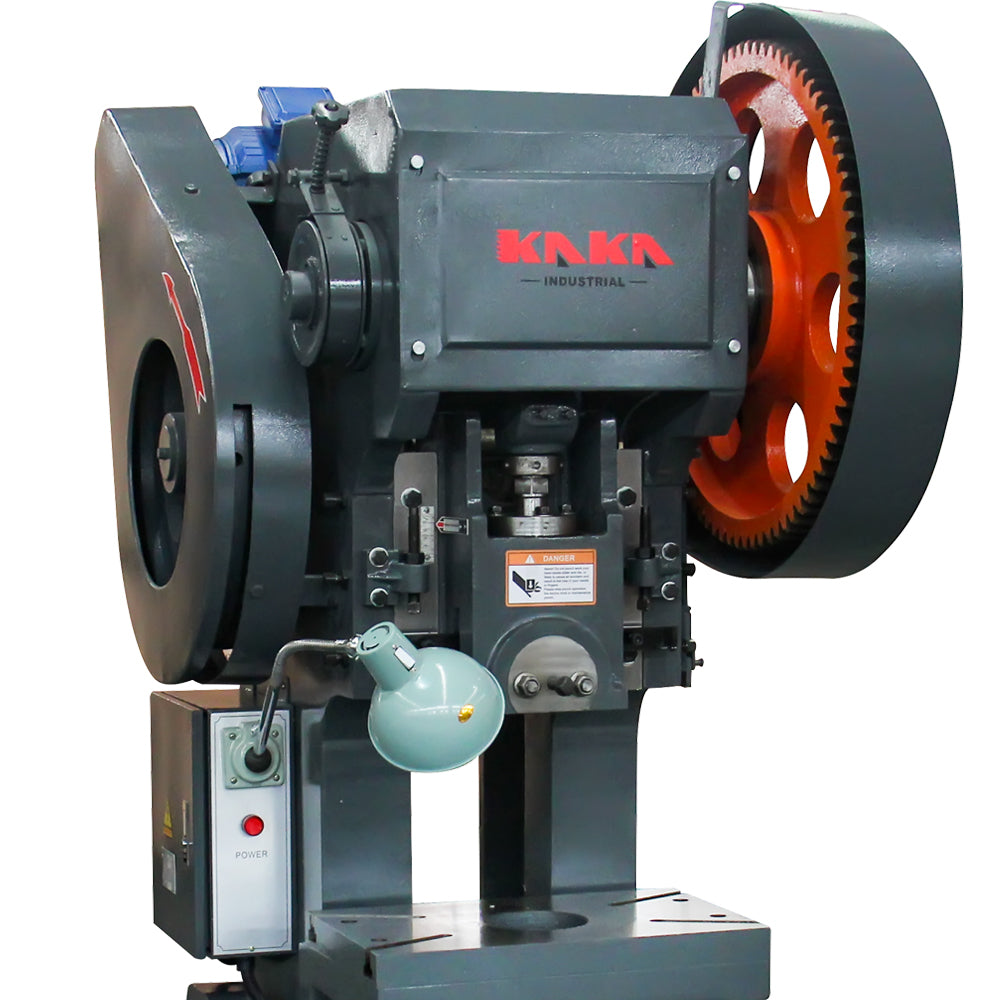

Kaka industrial JB23-25,25 Ton Mechanical Power Press Punching Manual Sheet Metal Punch Press Machine

JB23-25 punch press is a suitable open type crank press featuring a left and right open type machine body (i.e. C-shaped machine body). Its steel plate welded body has high shock-absorbing performance. Its throat has certain depth. The compact structure makes the use convenient and operation safe. Its working table is open on three sides, so the mold loading and unloading and operation are convenient. The punch press is widely used for it provides good conditions for mechanization and automation. And as main equipment for plate punching production, the punch press can be used for punching holes, blanking, trimming, bending, shallow stretching and forming in national defense, aerospace, automobile, tractor, motor, electrical appliance, bearing, instruments, agricultural machine and tool, bicycle, sewing, mechanical appliance,daily hardware and coinage departments.

- J23-25,25 Ton Manual Sheet Metal Punch Press Machine Open Eccentric Presses is a general-purpose presses, suitable for forming, blanking,punching,bending and other cold stamping processes.

- C-frame Casting fuselage, maximum rigidity and minimum deflection for accurate parts and long too life .body can be tilted, high rigidity and less deformation Compact. Thick plates and large columns provide you with the stable platform you need for your demanding application.

- The Machine uses Rigid rotated bond clutch rigid and well supported. The clutch gives continuous strokes for mass production.

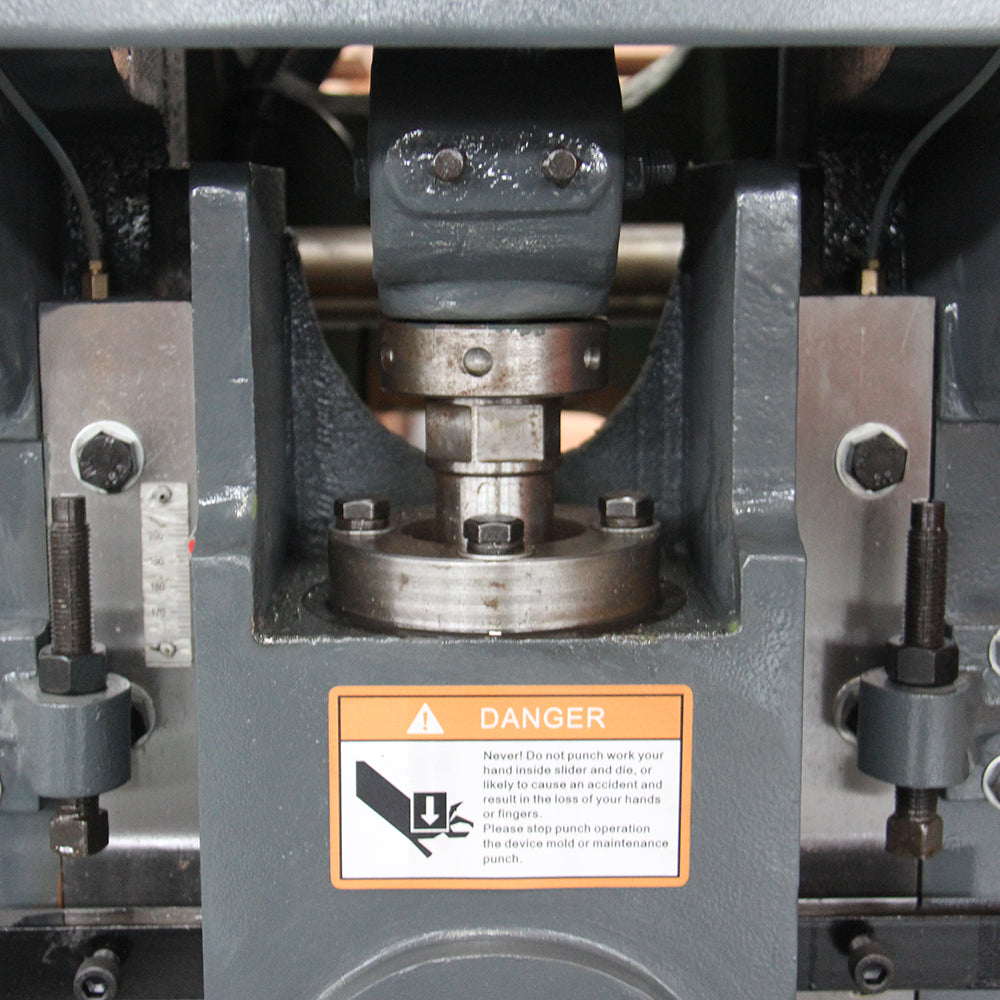

- Crankshaft is made of special alloy steel machined to close accuracy and fitted in bronze bushes for smooth working, longer life & accuracy.

- Properly sized flywheel, is made of high grade cast iron,for storing and releasing adequate energy for the pressing operations, and properly balanced for smooth running.

- Gear are of steel cast or fabricated. Gear teeth are generated by precision hobbing machine.

- Machine is with both hands button and footswitch control:anti-tie down, non-repeat controls with ring guards;conforms to OSHA.

- Protective fence and the safety interlock to ensure operation safety. Have a movable single-hand pedal switch, easy to operate.

| Spcification | Unit | ||

| Nominal force | kN | 250 | |

| Stroke under nominal force | in | 0.09 | |

| Slide block stroke | in | 2.75 | |

| Number of stroke | times/min | 65 | |

| Max die set height | in | 7.8 | |

| Die set height adjustment | in | 1.18 | |

| Distance from slide block center to the frame | in | 7.8 | |

| Workable dimensions(F·B×L·R) | in | 13.7*20.4 | |

| Dimensions of worktable hole | in | Φ4.7 | |

| Thickness of bolster | in | 1.96 | |

| Dimensions of slide block(F·B×L·R) | in | 6.69*8.6 | |

| Size of the handle hole(Diameter×Depth) | in | Φ1.5*2.3 | |

| Distance between columns of body | in | 9.4 | |

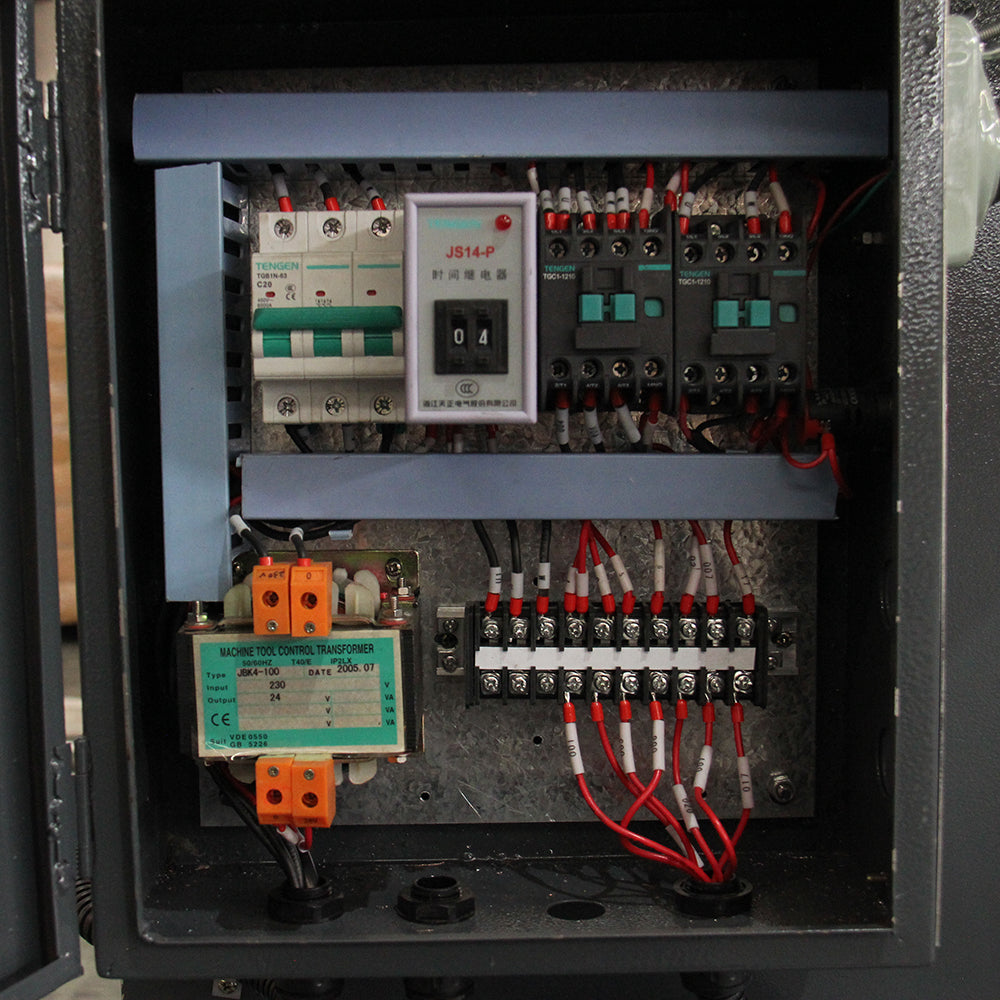

| Motor | Type | 220V/3phase | |

| Power | kw | 3 | |

| Max. tilting angel of body | º | 25° | |

| Outline dimension(F·B×L·R×H) | in | 85.8×40.1×54.7 | |

| N.W./G.W. | lb | 3638/3858 | |

Reviews

There are no reviews yet.