Description

EB-4816M Applicable Accessories Please click: here:https://www.kakaindustrial.com/collections/eb-4816m-applicable-accessories

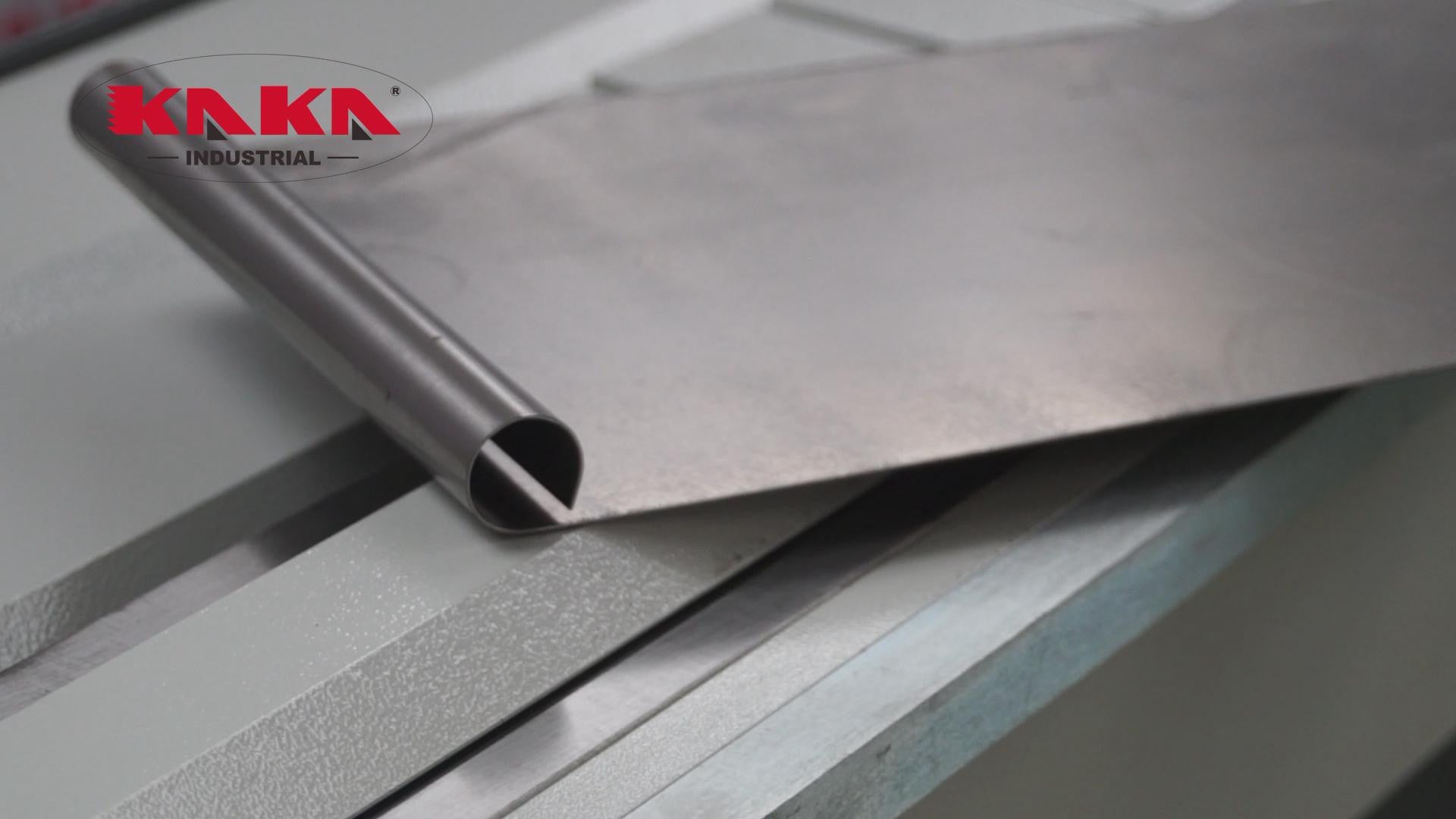

KAKA Industrial EB-4816 Manual Magnetic Sheet Metal Brake, Box and Pan Brake

- EB-4816 can bend boxes or pans to almost any depth since it doesn’t rely on conventional finger depths.

- 48-Inch Magnetic clamping Pan and Box Bending Brake,16-Gauge Mild Steel Capacity

- 6-ton magnetic power is consistent across the entire beam, allowing for crisp bends even in the middle of the brake.

- To achieve proper performance and prevent damage to the machine, the power supplied must be 220VAC . Failure to comply will damage the machine and void the warranty.

- The breakthrough open-ended design allows you to create enclosed ducts and shapes impossible to make with a traditional box and pan brake.

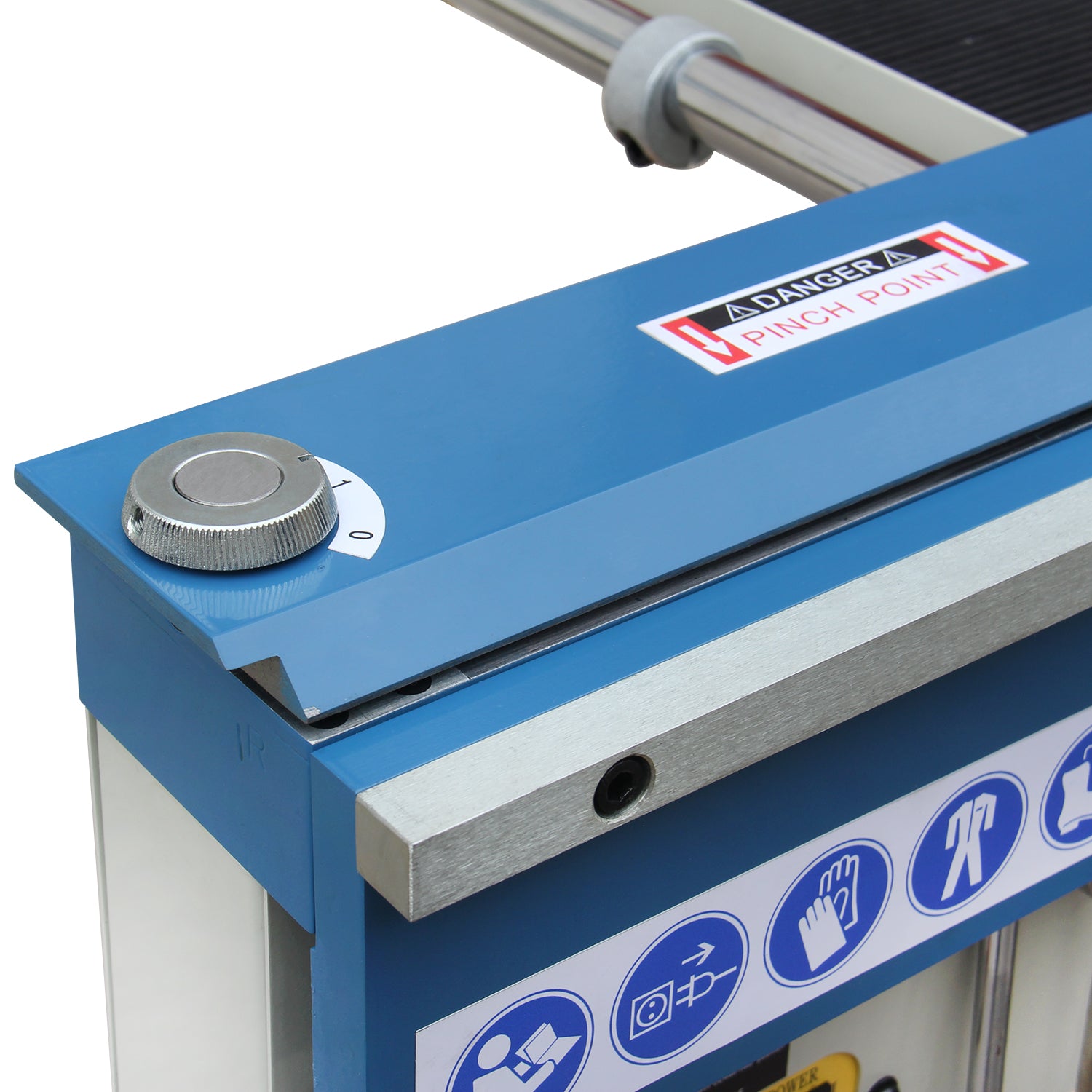

- Scaled stroke angle control lets you deliver repeatable bends time after time.

- You can set up the mild steel clamping bar with straight bars (of various widths if you had very tight boxes to make) for straight bends or segmented clamping bars for box and pan applications.

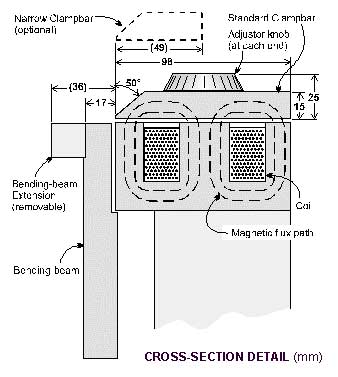

- Blade gap adjustment on the clamping bars lets you work with sheet metal of different thicknesses.

- You can remove the bottom leaf’s bending extension for the tightest bend dimension between bends of .625”.

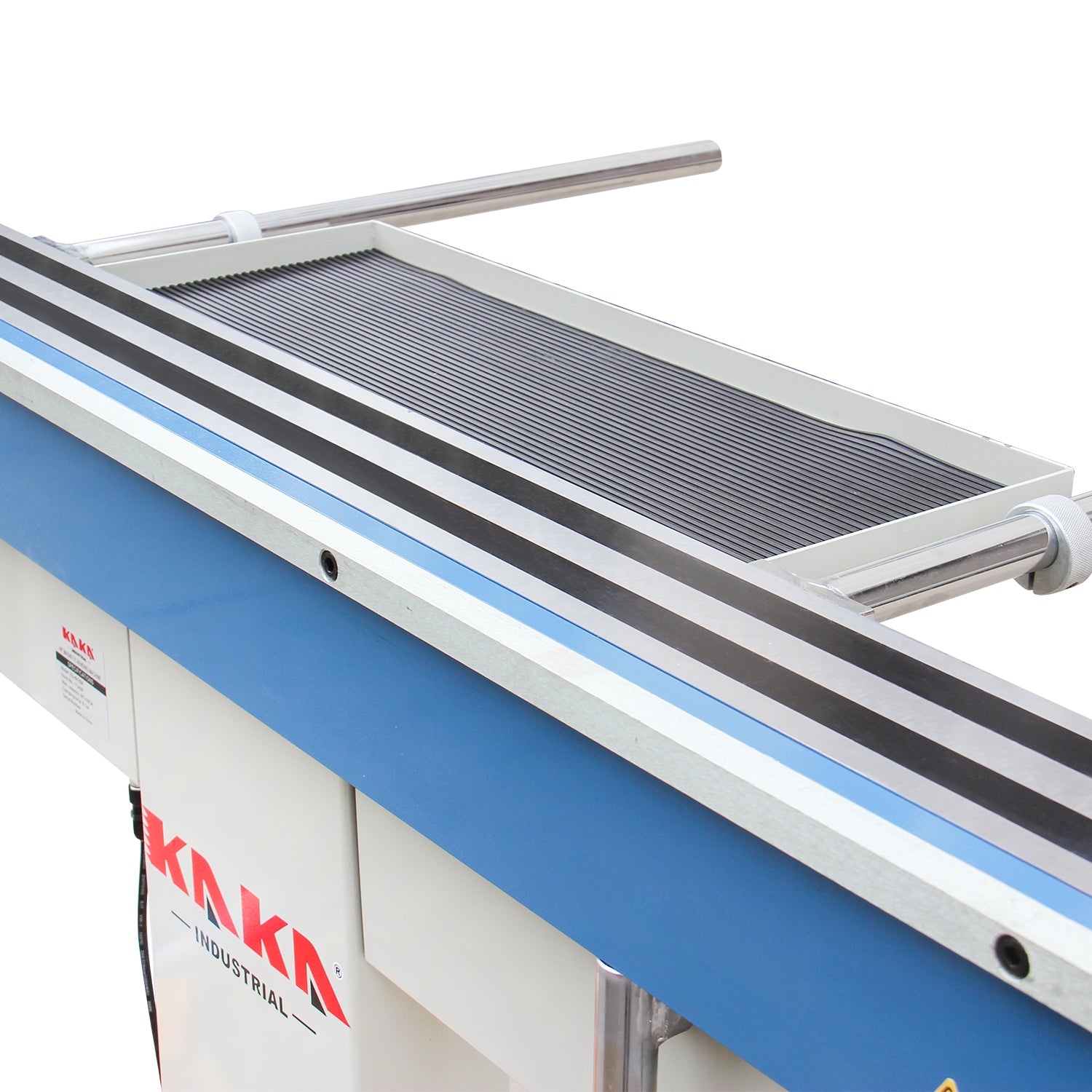

- Comes with product supports and adjustable back gauges for production runs.

- Kaka industrial covers this box brake with a 2-year parts warranty

Easy, hands-free operation:

Put a piece of material between the clamping bar to the depth required.

Engage the powerful magnet in the bending bed with push button control.

Hit the foot pedal that softly clamps the material. This foot control keeps your fingers safely out of the machine and you to reposition the material.

Lift the the bottom bending leaf to complete the bend.

Recommended for:

HVAC shops, industrial art shops, and general sheet metal fabrication shops.

Making enclosed boxes, triangles, alternate bends on varying planes, and round items such as scrolling applications.

Bending a variety of materials, including sheets of mild steel, stainless steel, aluminum, coated materials, heated plastics, and more.

Model:EB-4816

Max. Capacity with Extension 18ga. (1.21mm) mild steel / 21ga. (0.83mm) stainless steel

Max. Capacity without Extension 16ga. (1.51mm) mild steel / 20ga. (0.91mm) stainless steel

Max. Capaity (lengthxthikness):4×16 Ga.(1250×1.6mm)

Clamping foce: 6Ton

Duty cycle: 30%

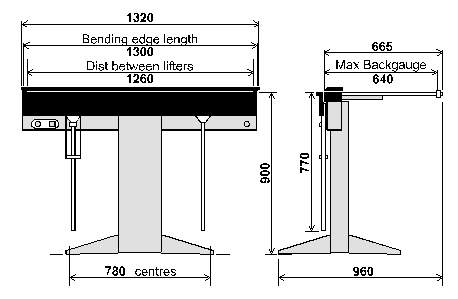

Back-gauge: 25in

Foot switch:Standard

Norminal current: 6Amp

Protection:Thermal cut-out 70℃

Bending-edge length: 51in

Distance between lifters: 49in

Packing size(in): 57x44x15

N.W/G.W.(lb): 390lbs / 485lbs

Clamp Bar & Segment fingers include:

(1) 52” x 2” Solid Clamp Bar

(1) 52” x 4” Solid Clamp Bar

(1) 52” x 4” Notched Adjustable Clamp Bar

(1) 11” x 4” Clamp Bar

(1) 5.5” x 4” Clamp Bar

(1) 2.75” x 4” Clamp Bar

(1) 2” x 4” Clamp Bar

(1) 1.5” x 4” Clamp Bar

(1) 1” x 4” Clamp Bar

Special Notes: Capacities can change depending on set up leaf extension. Rule of thumb for mild steel, 16ga., extension OFF. 18ga. extension On or Off, 20ga. and thinner, extension On.

Things to Know Before Purchase To achieve proper performance and prevent damage to the machine, the power supplied must be 220VAC +/-5% (209VAC to 231VAC). Failure to comply will damage the machine and void the warranty.

NOMINAL CAPACITY

1250 mm x 1.6 mm (4ft x 16g)

CLAMPING FORCE (with standard full-length clampbar)

6 Tonne

ELECTRICAL

Supply: 1 phase, 220V ac

Nominal current: 8 Amp

Duty cycle: 30%

Protection: Thermal cut-out, 70°C

BENDING CAPACITIES (for standard full-length clampbar)

|

MATERIAL |

THICKNESS |

LIP WIDTH |

BEND RADIUS |

|

Mild Steel |

1.6 |

30* |

3.5 |

|

1.2 |

15 |

2.2 |

|

|

1.0 |

10 |

1.5 |

|

|

Aluminium |

1.6 |

30* |

1.8 |

|

1.2 |

15 |

1.2 |

|

|

1.0 |

10 |

1.0 |

|

|

Stainless Steel |

1.0 |

30* |

3.5 |

|

0.9 |

15 |

3.0 |

|

|

0.8 |

10 |

1.8 |

* With Standard bending beam extension fitted. For most non-ferrous metals (copper, brass, zinc) refer to Aluminium above.

Reviews

There are no reviews yet.